“Accelerating Green Chemistry” is therefore one of the six focus topics of the Fraunhofer Chemistry Alliance. It pools the expertise, methods, facilities, and infrastructure of the Fraunhofer institutes to support the chemical industry and related sectors in their transformation towards sustainability and to accelerate this transformation.

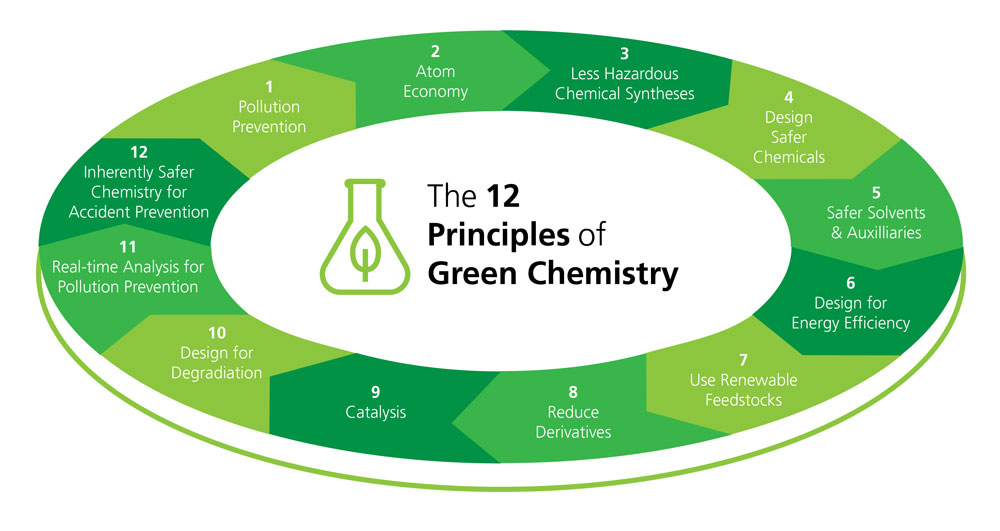

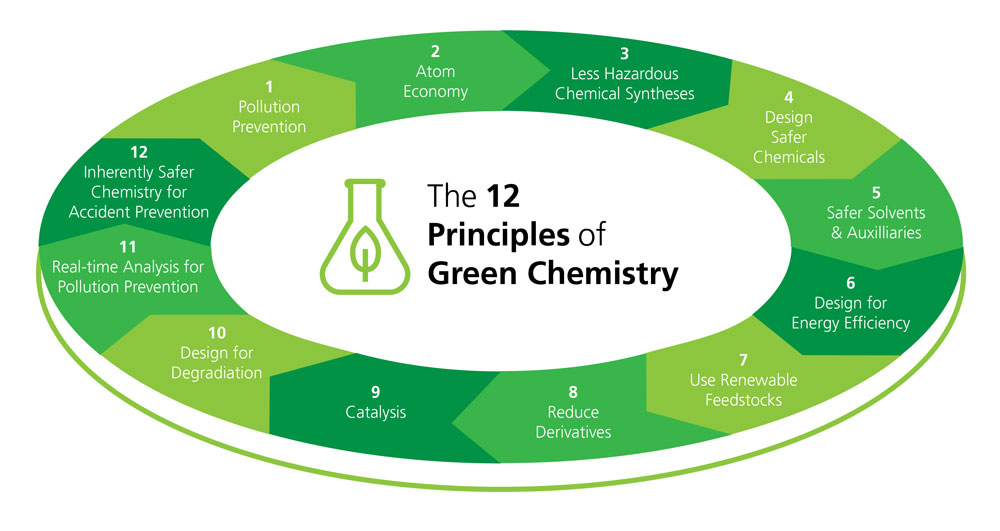

Principles of Green Chemistry and Green Engineering

The term “green chemistry” is not new per se. The “12 Principles of Green Chemistry” were introduced in the late 1990s as a postulate for sustainable, environmentally and resource friendly chemistry and were later expanded to include the “12 Principles of Green Engineering”. These principles now serve as guidelines for green, sustainable chemical products and processes in all product areas of chemistry, both in research and industry. This concerns all sorts of things of daily life, from vehicles to personal care and medicine.

© Fraunhofer IMM

“Green Chemistry” – From Raw Materials to Process to Product

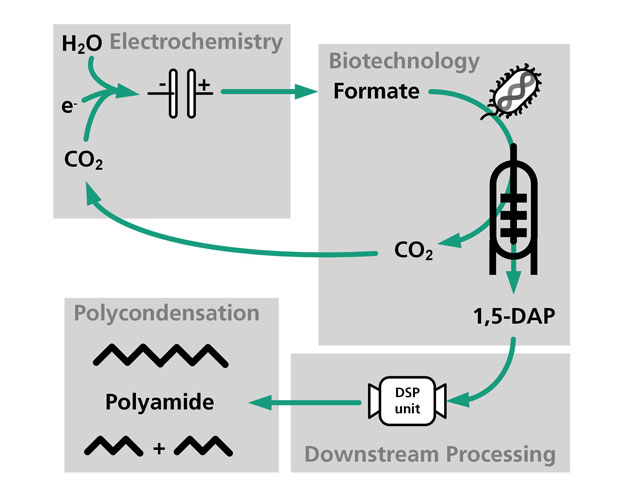

Ideally, green chemistry begins with the selection of raw materials and leads to a green product through a green design of production processes.

For example, methods and products of modern bioeconomy can be used to provide renewable raw materials and other biogenic carbon sources as an alternative to fossil raw materials. The use of carbon dioxide and recyclates as raw material sources is also part of the strategy to become independent of fossil materials.

Process intensification and catalysis are essential aspects of the green design of production processes, e.g., by minimizing the use of energy and the amount of chemicals in the active process and enabling selective conversions with high yields. In particular, work-up processes must be taken into account. Ideally, they would not be necessary if the manufacturing processes could be perfectly controlled. However, work-up processes are also a key element for the success of bio-based products, where unwanted side products and impurities need to be separated from the main product, requiring innovative process solutions.

Ideally, in the end, the result is a non-hazardous product with good biodegradability and the ability to be recycled at a high value level.

The application of Life Cycle Analysis and Green Metrics allows the qualitative and quantitative evaluation and assessment of the entire chain of green raw materials – green processes – green products regarding a transformation towards sustainability. For example, different approaches can be compared. Then the best one can be selected for further pursuit, taking into account technoeconomic requirements.

The Fraunhofer Chemistry Alliance deals with all aspects of Green Chemistry and offers its expertise for a sustainable design of the chemical industry, the industries based on it and thus society.